Industrial and Rugged Designs

The term “Ruggedization” refers to designs that are tested at high temperatures with high yield fallout. Rugged sub-systems and systems are built to withstand the harshest environments. Ruggedization involves reinforcing the hardware to endure extreme temperatures, moisture, dust, vibrations, and physical shocks. Rugged design techniques include using robust materials, implementing protective enclosures, and applying conformal coatings to shield sensitive components. Rugged systems designed are constructed so as not to fail under the most difficult operating conditions.

Rugged Designs is done built to withstand one or more conditions typically found in harsh environments like excessively temperatures, moisture and high/low pressure, mechanical vibration or shock, electrical discharge at high voltage/ current and particle matter such as dust. For truly Rugged boards and systems, they need to be designed for harsh environment from the ground up. To ensure ruggedness, special attention and care needs to be given to component selection; circuit design; printed circuit board (PCB) thickness, layout, and materials; thermal solutions; enclosure and mechanical design; and manufacturing process for ensuring a Rugged System Design.

Product Ruggedization Services

Mistral’s is an embedded product and industrial design company offering development of custom industrial designs and enclosures keeping in mind aesthetics, durability, ruggedization, EMI/EMC protection, safety compliance and product cost. We use best-in-class rugged design techniques to ensure that products designed by us operate reliably in extremes of temperature, shock, vibration, and environment. To address the requirements of our aerospace and defense customers, our industrial and rugged designs offer standard hardware architectures which include VPX, OpenVPX, VXS, VME and other VITA and PICMG standards and custom, non-standard hardware.

Our industrial design and rugged system design services address the four key characteristics of ruggedization: Shock, vibration, temperature, and ingress protection (IP). Mistral has the latest, state-of-the-art 3D CAD systems for industrial designs, as well as a variety of equipment and tools for mechanical analysis and testing. As an Industrial Design company, we use the best available methodologies and techniques to ensure that our rugged product designs operate reliably in extremes of temperature, shock, vibration, & environment. Our partnerships with leading manufacturing and environmental testing facilities help us achieve quick turnaround and adhere to strict quality control processes as specified by ISO 9001 and AS9100D standards. Mistral’s product rugged design services includes analysis of thermal and vibration in the initial design stages by computer simulation.

Rugged Designs

Mistral’s industrial and rugged system design or ruggedization services for aerospace and defense applications incorporate the latest air, conduction and AFT techniques to help optimize performance, conform to ATR standards like ½ ATR, ¾ ATR, 1 ATR and support a variety of thermal management methods. To ensure our systems perform reliably for long periods of time and in extreme environments, we put extensive time and effort into rigorous thermal testing and analysis.

Mistral’s industrial and rugged system design or ruggedization services for aerospace and defense applications incorporate the latest air, conduction and AFT techniques to help optimize performance, conform to ATR standards like ½ ATR, ¾ ATR, 1 ATR and support a variety of thermal management methods. To ensure our systems perform reliably for long periods of time and in extreme environments, we put extensive time and effort into rigorous thermal testing and analysis.

Our team of experienced engineers with their knowledge and capability in design tools and ruggedizing techniques ensure delivery of Industrial and rugged designs optimized for functionality and manufacturability. Thermal management is one of the key requirements for rugged designs, specifically for aerospace and defense applications that require high processing power. Our rugged system design and ruggedizing process is based on shock, vibration, temperature and Ingress Protection. To cater to the rugged needs of the consumer market, we offer industrial designs that are FCC/CE compliant and meet key product considerations like styling and appearance, EMI/EMC protection, thermal cooling for internal components, ruggedizing for drop shock and environmental stress, safety compliance and ease of assembly.

Expertise

Concept Engineering

- Rugged Enclosure design requirement

- Feasibility study of Rugged Designs w.r.t. conforming to industrial/defense/aerospace standards

- Material science management

- Rugged system Design with EMI/EMC shielding and Gaskets

- Alloys for specific application

- Fasteners

Rugged Designs

- 3D CAD modeling and design

- Structural analysis

- Thermal Management and EMI/EMC shielding

- Integration of electronics design, PCB layout, industrial and rugged designs

- Prototype development

- Manufacturing support

Thermal Management Methods

- Ruggedizing for

- Convection cooled

- Air flow-through

- Conduction cooled

- Forced air conduction cooled

- Liquid cooled

Compliance standards

- FCC/CE standards

- MIL standards for environmental compliance and ruggedization

- MIL-STD-810 environmental compliance

- MIL-STD-901D shock qualified enclosures

- MIL-STD-167 vibration qualified enclosures

- MIL-STD-461 / EMI / RFI / tempest secure systems

- JSS 55555 standards

Ruggedization Tests

- FCC/CE standards

- MIL standards for environmental compliance and ruggedization

- MIL-STD-810 environmental compliance

- MIL-STD-901D shock qualified enclosures

- MIL-STD-167 vibration qualified enclosures

- MIL-STD-461 / EMI / RFI / tempest secure systems

- JSS 55555 standards

Ruggedization Tests

- Power Burn-in, Random Vibration, Shock, Thermal Cycling

- High/low temperature storage cum operation

- Low Pressure (Altitude), Humidity Test

- Driving rain and drip Test, Dust Test

- Fungus Test, Saltfog Test, Fluid Contamination Test

- Acceleration Test, Bench Handling

- Transit Drop Test

- EMI/EMC, Power Supply, Insulation and Bonding

Concept Engineering

- Rugged Enclosure design requirement

- Feasibility study of Rugged Designs w.r.t. conforming to industrial/defense/aerospace standards

- Material science management

- Rugged system Design with EMI/EMC shielding and Gaskets

- Alloys for specific application

- Fasteners

Rugged Designs

- 3D CAD modeling and design

- Structural analysis

- Thermal Management and EMI/EMC shielding

- Integration of electronics design, PCB layout, industrial and rugged designs

- Prototype development

- Manufacturing support

Thermal Management Methods

- Ruggedizing for

- Convection cooled

- Air flow-through

- Conduction cooled

- Forced air conduction cooled

- Liquid cooled

Compliance standards

- FCC/CE standards

- MIL standards for environmental compliance and ruggedization

- MIL-STD-810 environmental compliance

- MIL-STD-901D shock qualified enclosures

- MIL-STD-167 vibration qualified enclosures

- MIL-STD-461 / EMI / RFI / tempest secure systems

- JSS 55555 standards

Ruggedization Tests

- FCC/CE standards

- MIL standards for environmental compliance and ruggedization

- MIL-STD-810 environmental compliance

- MIL-STD-901D shock qualified enclosures

- MIL-STD-167 vibration qualified enclosures

- MIL-STD-461 / EMI / RFI / tempest secure systems

- JSS 55555 standards

Ruggedization Tests

- Power Burn-in, Random Vibration, Shock, Thermal Cycling

- High/low temperature storage cum operation

- Low Pressure (Altitude), Humidity Test

- Driving rain and drip Test, Dust Test

- Fungus Test, Saltfog Test, Fluid Contamination Test

- Acceleration Test, Bench Handling

- Transit Drop Test

- EMI/EMC, Power Supply, Insulation and Bonding

BLOCK DIAGRAM

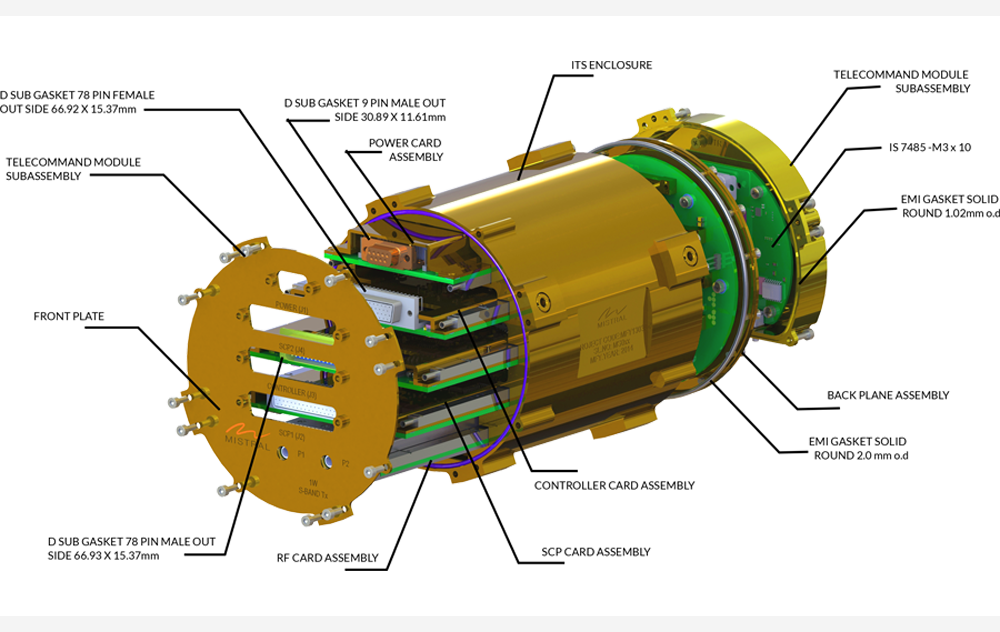

An expanded isometric view of a Rugged System Design